Silver manufacturing stands as a testament to the intersection of artistry and precision engineering. From the meticulous shaping of raw materials to the final polishing of finished pieces, this process embodies a tradition of excellence that spans centuries. In this article, we delve into the intricate world of silver manufacturing, exploring the craftsmanship, techniques, and innovation that define this timeless industry.

Craftsmanship at Its Finest: At the heart of silver manufacturing lies a tradition of skilled craftsmanship passed down through generations. Master artisans employ a blend of traditional techniques and modern innovations to transform raw silver into exquisite works of art. Whether handcrafted or machine-made, each piece undergoes a meticulous process that emphasizes attention to detail and uncompromising quality.

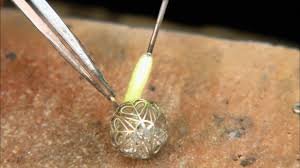

Techniques and Processes: The silver manufacturing process encompasses a diverse range of techniques, each tailored to achieve specific shapes, textures, and finishes. Casting, forging, and stamping are among the most common methods used to shape silver into desired forms, while techniques such as engraving, filigree, and repoussé add intricate details and embellishments. From the initial design phase to the final assembly, every step in the manufacturing process is executed with precision and care.

Innovation and Technology: While traditional craftsmanship forms the foundation of silver manufacturing, innovation and technology play an increasingly significant role in driving progress and efficiency. Advanced machinery, computer-aided design (CAD) software, and automation have revolutionized certain aspects of the manufacturing process, enabling greater precision, consistency, and scalability. Moreover, sustainable practices and ethical sourcing are becoming increasingly important considerations, driving innovation in materials, processes, and supply chain management.

The Enduring Legacy of Excellence: As consumers continue to seek authenticity and quality, the allure of handcrafted silver remains as strong as ever. Whether adorning tabletops with gleaming silverware or showcasing statement jewelry pieces, silver manufactured with care and precision adds a touch of elegance and sophistication to any setting. Moreover, as artisans and manufacturers embrace innovation and sustainability, the future of silver manufacturing shines bright with promise and possibility.

In conclusion, silver manufacturing represents the perfect marriage of tradition and innovation, craftsmanship and technology. As we celebrate the artistry and ingenuity that define this timeless industry, we honor a legacy of excellence that continues to inspire and captivate. Whether preserving age-old techniques or embracing cutting-edge advancements, silver manufacturers play a vital role in shaping the aesthetic and cultural landscape of our world.

Crafting Elegance: The Art of Manufacturing Silver Jewelry

Manufacturing silver jewelry is a harmonious blend of creativity, skill, and precision. From the initial design concept to the final polishing, each piece undergoes a meticulous process that transforms raw materials into wearable works of art. In this article, we delve into the enchanting world of manufacturing silver jewelry, exploring the craftsmanship, techniques, and innovation that define this captivating industry.

Unveiling the Creative Process: At the heart of manufacturing silver jewelry lies a boundless realm of creativity. Designers draw inspiration from a myriad of sources – nature, culture, history – to conceive designs that evoke emotion and style. Whether crafting timeless classics or avant-garde creations, the design process is characterized by experimentation, iteration, and a deep understanding of materials and techniques.

Precision Techniques and Expertise: Once a design is finalized, skilled artisans bring it to life through a series of precision techniques. Casting, soldering, and stone setting are just a few of the methods used to shape and assemble silver jewelry components. Each step demands meticulous attention to detail and a mastery of technique, ensuring that every element aligns seamlessly to create a cohesive and harmonious piece.

Innovation in Manufacturing: While traditional techniques form the foundation of silver jewelry manufacturing, innovation and technology play an increasingly vital role in driving progress and efficiency. Advanced machinery, such as laser cutting and 3D printing, streamline production processes and enable greater design flexibility. Moreover, digital tools and software aid in design visualization and prototyping, accelerating the development cycle and fostering creativity.

Embracing Sustainability and Ethics: As consumers become more conscientious about their purchasing decisions, sustainability and ethical sourcing have become paramount considerations in the jewelry industry. Manufacturers are embracing responsible practices, such as recycled silver and fair trade sourcing, to minimize environmental impact and support ethical supply chains. By prioritizing sustainability, manufacturers uphold their commitment to preserving the beauty of our planet for future generations.

In conclusion, manufacturing silver jewelry is a labor of love that celebrates the timeless beauty of this precious metal. From the artisanal workshops to state-of-the-art manufacturing facilities, each piece is imbued with the passion and dedication of the craftsmen who bring it to life. As we adorn ourselves with these exquisite creations, we not only enhance our personal style but also honor the artistry and heritage of silver jewelry manufacturing.